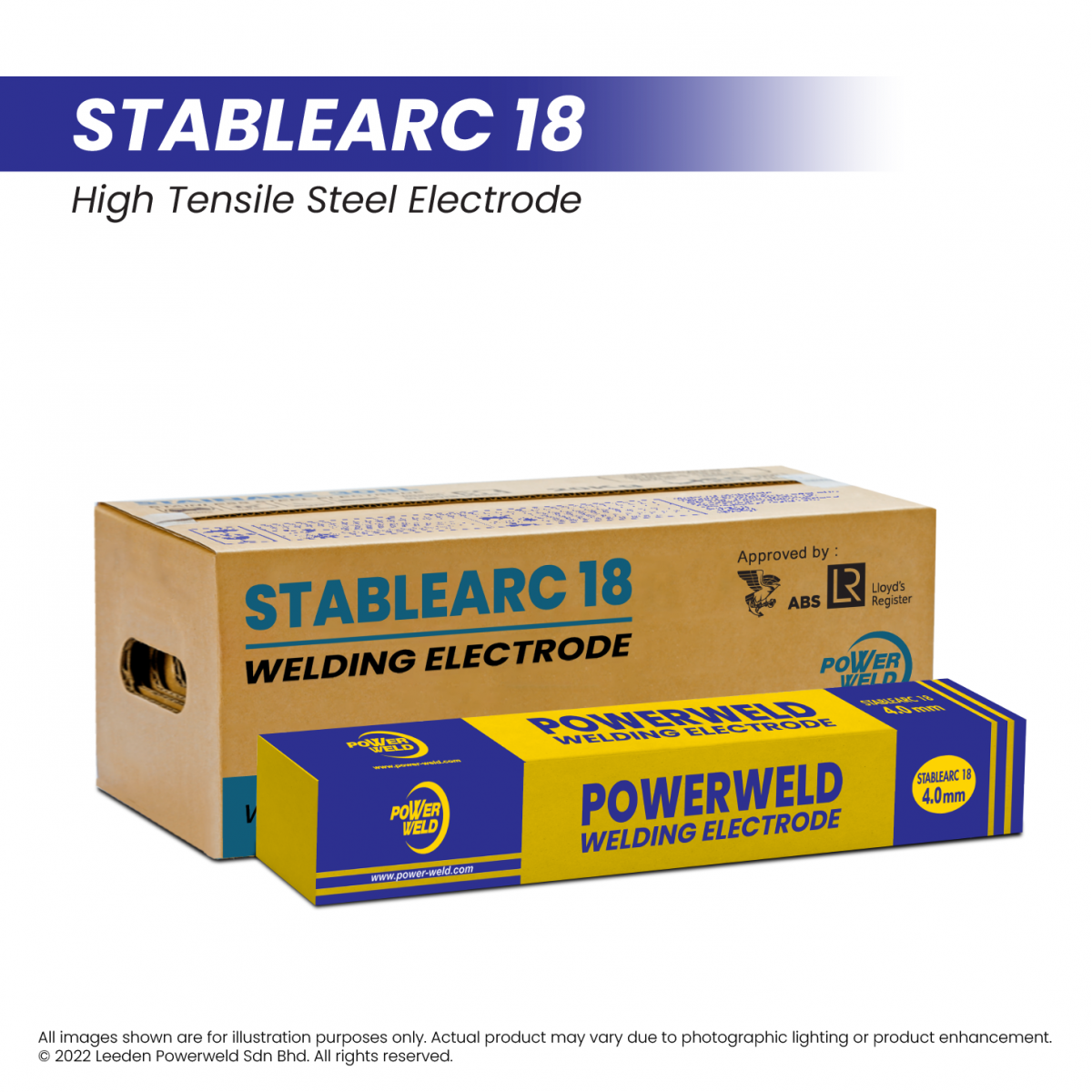

STABLEARC 18

A smooth running, basic iron powder, low hydrogen electrode offering outstanding performance in all positions (except vertical down) on both AC and DC welding currents. Typical applications include the welding of pressure vessels, pipes, heavy structural grinders and beams, tanks, earth moving and mining equipment, repair, and maintenance.

Classifications:

- AWS A5.1: E7018

- EN ISO 2560-A: E 42 3 B 32 H10

- EN ISO 2560-B: E 49 18 A U H10

- JIS Z3211: E4918

SHARE

STABLEARC 18 is a smooth running, basic iron powder, low hydrogen electrode offering outstanding performance in all positions (except vertical down) on both AC and DC welding currents. The controlled C-Mn weld deposit chemistry of the STABLEARC 18 gives excellent low-temperature toughness at temperatures down to -20˚C in the as-welded and stress-relieved conditions.

- Basic Iron Powder Coating

- “Low” Hydrogen Status

- All Position Capabilities Except Vertical Down

With good operator appeal and low-temperature impact properties, it will be readily accepted for use in application both in the fabrication shop and outside construction sites. Typical applications include the welding of pressure vessels, pipes, heavy structural grinders and beams, tanks, earth moving and mining equipment, repair, and maintenance.

Reconditioning Recommendations:

For the maintenance of the “H10 and H8” low hydrogen categories. The electrode should be rebaked for a maximum of 2 hours @ 300˚C (570˚F) in a vented oven and thereafter use from a hot box set at 100-120˚C (210 – 250˚F). Cardboard packs of STABLEARC 18 may lose their designated hydrogen status due to moisture re-absorption from the poor storage environments. Where electrodes have been exposed to moisture or where hydrogen control is important, the above procedures are recommended for reconditioning.

Operational and Packaging Data:

- Electrode size: 2.6mm, 3.2mm, 4.0mm, and 5.0mm.

- Electrode length: 300mm and 400mm.

- Electrode packaging: 5kg and 20kg.

*Recommended for DC+ or AC (minimum 70 OCV) operation.

Request For Quote

Related Products

Get Answers To All Questions That You May Have

Phone:

(+60) 6 232 3288

(+60) 6 232 3286

(+60) 16 229 7305

Fax:

(+60) 6 232 3200

Factory 1

No.168, Jalan Usaha 12,

Kawasan Perindustrian

Ayer Keroh,

75450, Ayer Keroh, Melaka

Factory 2

131-C, Jalan Usaha 5,

Kawasan Perindustrian Ayer Keroh,

75450 Melaka, Malaysia

Factory 3

127-A, Lot 61 Jalan Usaha 9,

Kawasan Perindustrian Ayer Keroh,

75450 Melaka, Malaysia